Customer Stories 29/11/2022

VISO, Belgium's largest graphic secondary school, has invested in a Summa F1612 as part of a new future-proof curriculum. The aim is to prepare students for an amazing future in the graphic industry or higher education. With this cutting table, pupils learn both to develop projects from budding ideas to full-fledged products and to go through the whole production process.

With 800 pupils and a team of 105 teachers, VISO, located in Ghent, is Belgium's largest graphic secondary school. The school offers both creative and technical graphics disciplines, such as photography, graphic media, print media, and publicity design.

In recent years, the school has invested heavily in developing a new graphics curriculum to future-proof their courses. VISO investigated how they could better prepare their pupils for the professional field or higher education.

This investigation resulted in the decision to focus more on project education and to expand their workshop further to include the latest precision milling and cutting technologies.

A cutting machine is quite an investment, particularly for a school. Therefore, it is crucial that the machine they choose fits all their requirements:

To find the perfect cutting table, VISO conducted a study tour of different cutting table manufacturers, which led them to Summa.

The school then attended several demos both at their dealer, Papyrus, and at Summa's Experience Centre. They also interviewed people in the graphic sector who use a Summa.

This convinced them of Summa's user-friendliness, versatility, and safety. The extensive services and support in Belgium also helped them make the choice.

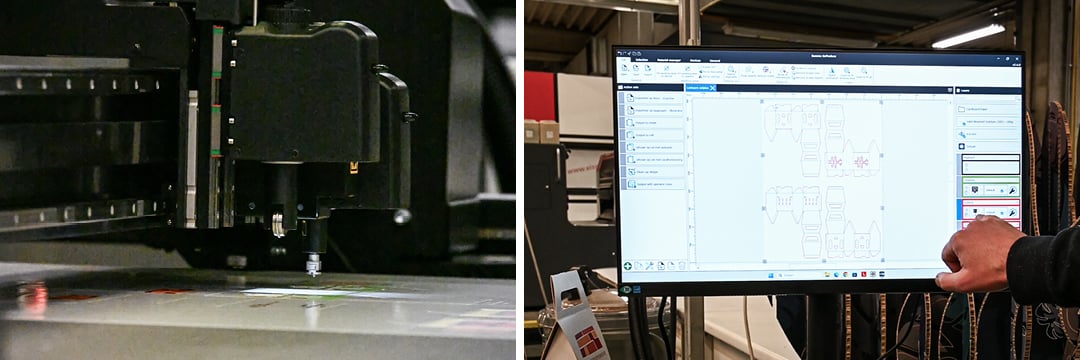

In the end, VISO chose the Summa F1612 flatbed cutter with a conveyor extension and milling unit, with the possibility of purchasing more tools in the future.

With the acquisition of the F1612, students can now see their creations come to life, which gives them a big boost. Previously, it was only possible to print and cut paper sheets, which meant many projects came to an end at the digital stage. Now, they can cut and print many more materials.

The teachers also encourage the students to experiment with the F1612. “We want them to experience everything the machine is capable of, but also to find its limits, " explains Leen Van Severen, Graphic Design Teacher at VISO.

Because the school is project-based, students go through the whole process from idea to finished product, allowing the pupils to get a taste for a real-life working environment.

One of VISO’s main criteria was the broad spectrum of applications the flatbed cutter can produce, and the F1612 delivered. Here are some examples for which the school has already used the Summa cutter:

These projects do not only come from the school. External parties, such as non-profit and other non-commercial organisations, can propose projects as well!

After four months of working with the F1612, VISO has nothing but praise. It opened up a whole new world of possibilities for the school. They knew they wanted a versatile flatbed cutter, but even then, they were surprised by how much they could actually do with the Summa F1612.

“We see no obstacles, only opportunities," says Bart Verstappen, VISO's Technical Advisor.

In fact, Verstappen says the only problem they have with the F1612 is that the waiting list to use it is becoming too long, "a good problem to have".

The Summa F1612 is the perfect fit for a graphic school like VISO. Its versatility, durability, safety, and user-friendliness have convinced the school to invest.

The students can now go through the entire production process and see their project come to life. Encouraging them to create even more! The teachers are also big fans of the flatbed cutter, creating many fun projects with external parties.

With this investment, Summa and VISO are preparing pupils for a bright future in the graphic sector.

Want to know more about the F1612 and our other flatbed cutter models? Check out the webpage or contact us.